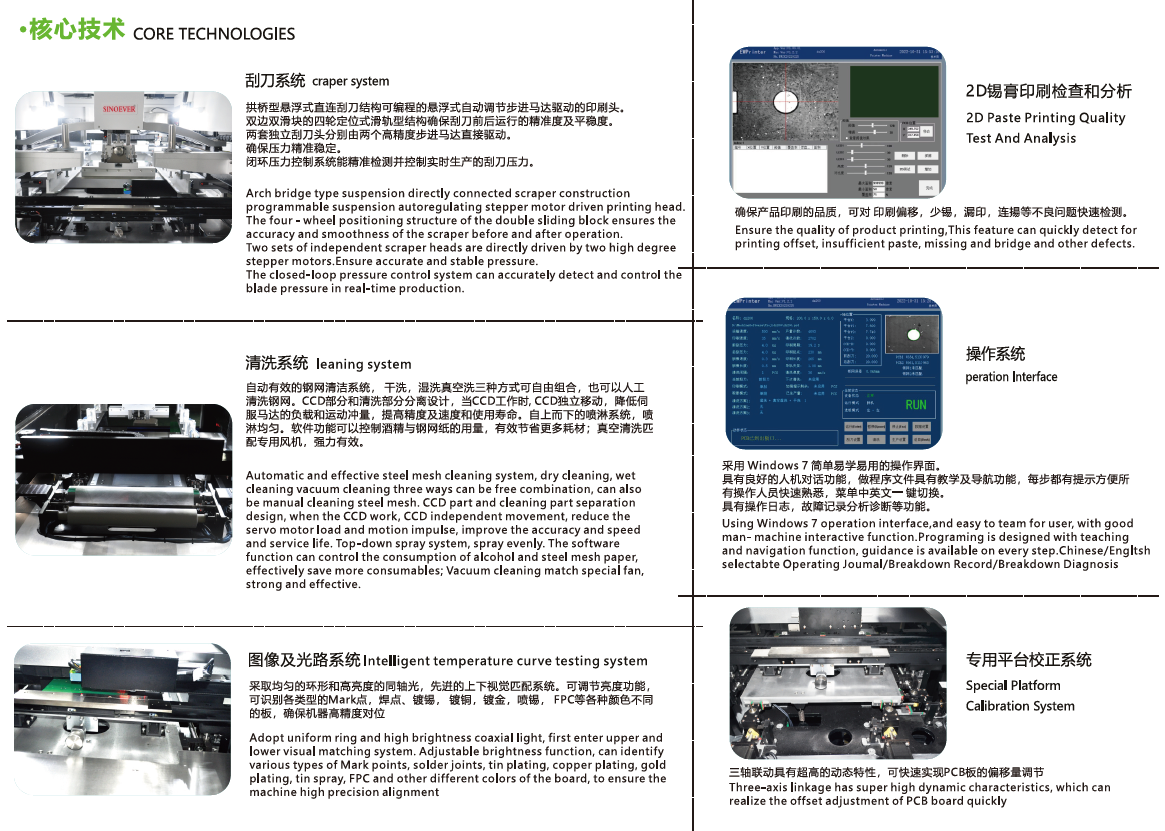

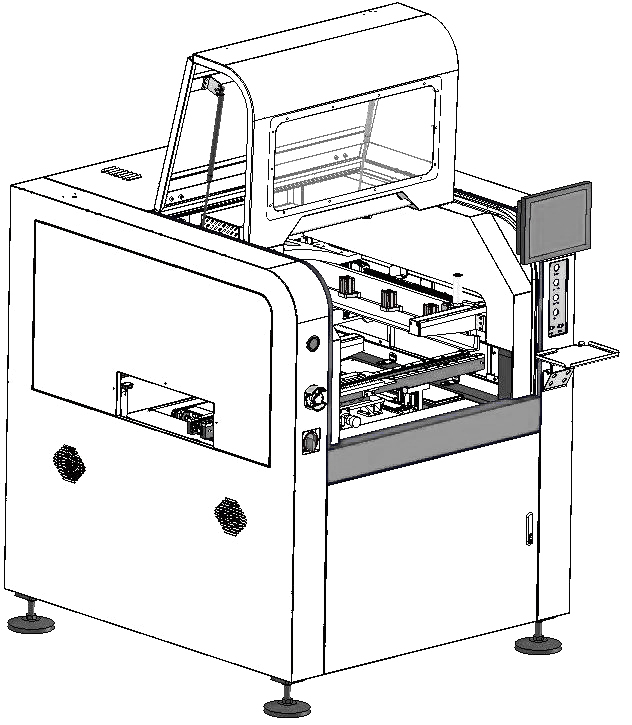

由高精度的图像视觉系统精确识别并计算出PCB Mark与钢网Mark间的偏差值,由PC控制工作台完成校准;在印刷锡膏时,锡膏受刮刀的推力产生滚动的前进,所受到的推力可分解为水平方向的分力和垂直方向的分力。当运行至模板窗口附近,垂直方向的分力使粘度已降低的锡膏顺利地通过窗口可印刷到PCB焊盘上,当平台下降后便留下精确的锡膏图形。

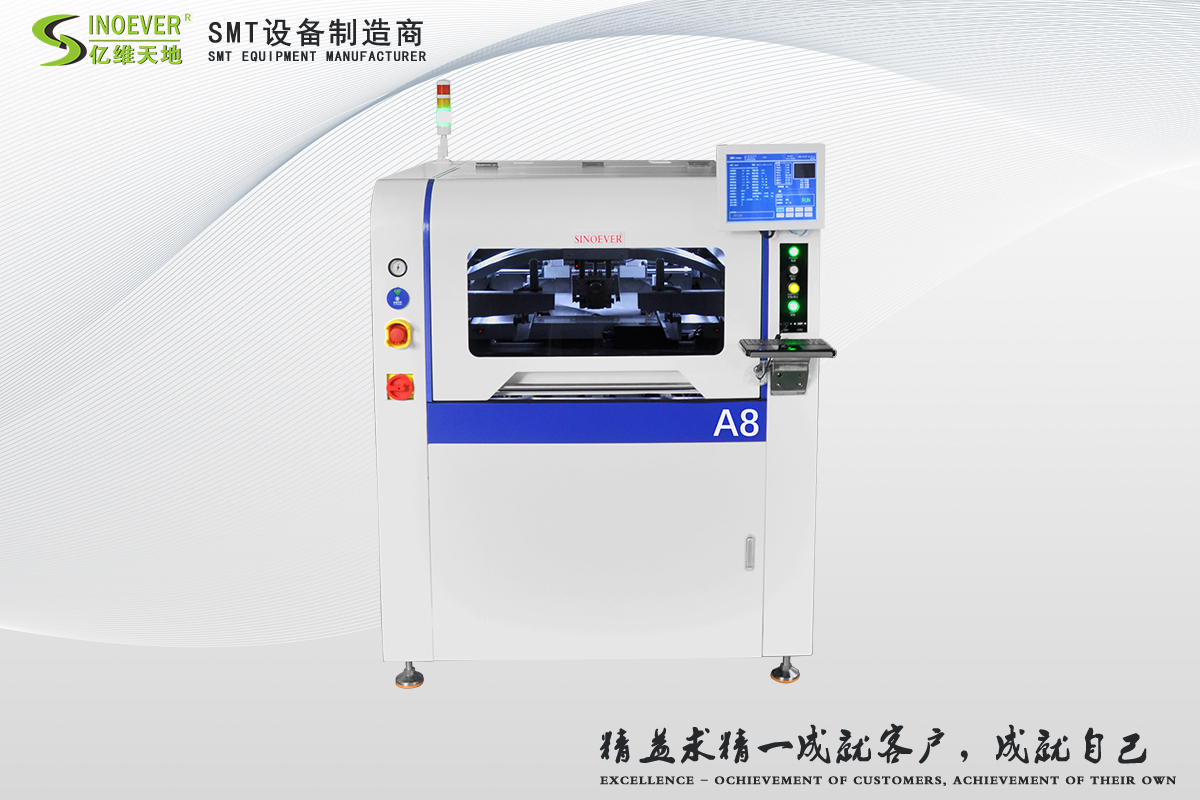

产品描述

本机包括机械、电气两大部分。

The machine consists of a mechanical part and an electric part.

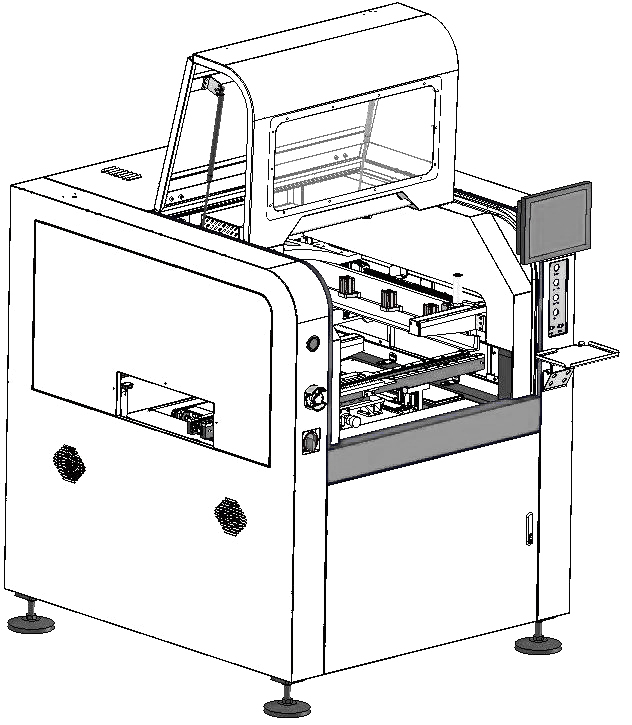

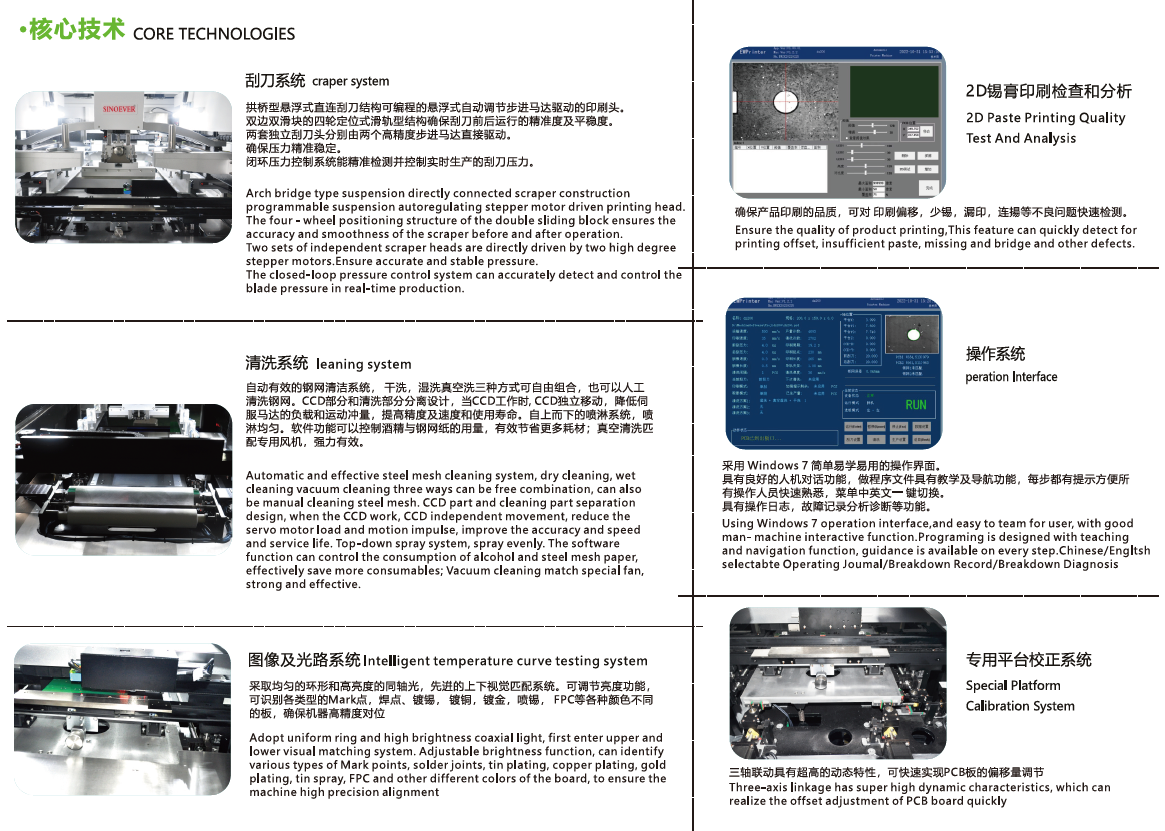

机械部分由运输系统、网板夹持装置、PCB夹板装置、视觉系统、刮刀系统自动网板清洗装置、可调工作平台等组成。

The mechanical part shall include the transport system, screen clampingdevice, PCB clamping board device, viewing system, squeegee system,auto screen-cleaning device adjustable workbench etc.

电气部分由工控机及控制软件、驱动器、步进电机、伺服电机和气动系统以及信号监测系统组成。

The electric part shall include the industrial PC and the control software,driver unit, step motor, servomotor, pneumatic system and signalmonitoring system etc.

由高精度的图像视觉系统精确识别并计算出PCB Mark与钢网Mark间的偏差值,由PC控制工作台完成校准;在印刷锡膏时,锡膏受刮刀的推力产生滚动的前进,所受到的推力可分解为水平方向的分力和垂直方向的分力。当运行至模板窗口附近,垂直方向的分力使粘度已降低的锡膏顺利地通过窗口可印刷到PCB焊盘上,当平台下降后便留下精确的锡膏图形。

The deviation between PCB Mark and steel Mark is accurately identified and calculatedby the high-precision image vision system, which is controlled by PCB Make the platformto complete the calibration; When printing solder paste, the solder paste is pushed by thescraper to produce rolling forward, and the thrust received can be decomposed intoThehorizontal component and the vertical component. When running near the template windowthe vertical component reduces the viscosityThe solder paste can be printed on the PCB padsmoothly through the window, and the precise solder paste pattern will be left after the platform drops